Top 5 reasons why you should add CAE to your CAD

December 11th, 2019

We all know that CAD means Computer-aided design since the mid 1980s, don’t we? There also exist other computer-aided technologies (i.e CAx acronyms), some of them being directly related to CAD and the PLM workflow. Such is the case of Computer-Aided Engineering or CAE, which is also known as finite-element analysis or FEA (due to the mathematical method usually used to solve the elasticity or thermal equations). Sometimes, as in the Onshape App Store, CAE is referred to plainly as “simulation” although I prefer the term “modeling.” In any case, here are five reasons why it is a good idea to add CAE to your CAD.

5. Know what is going on

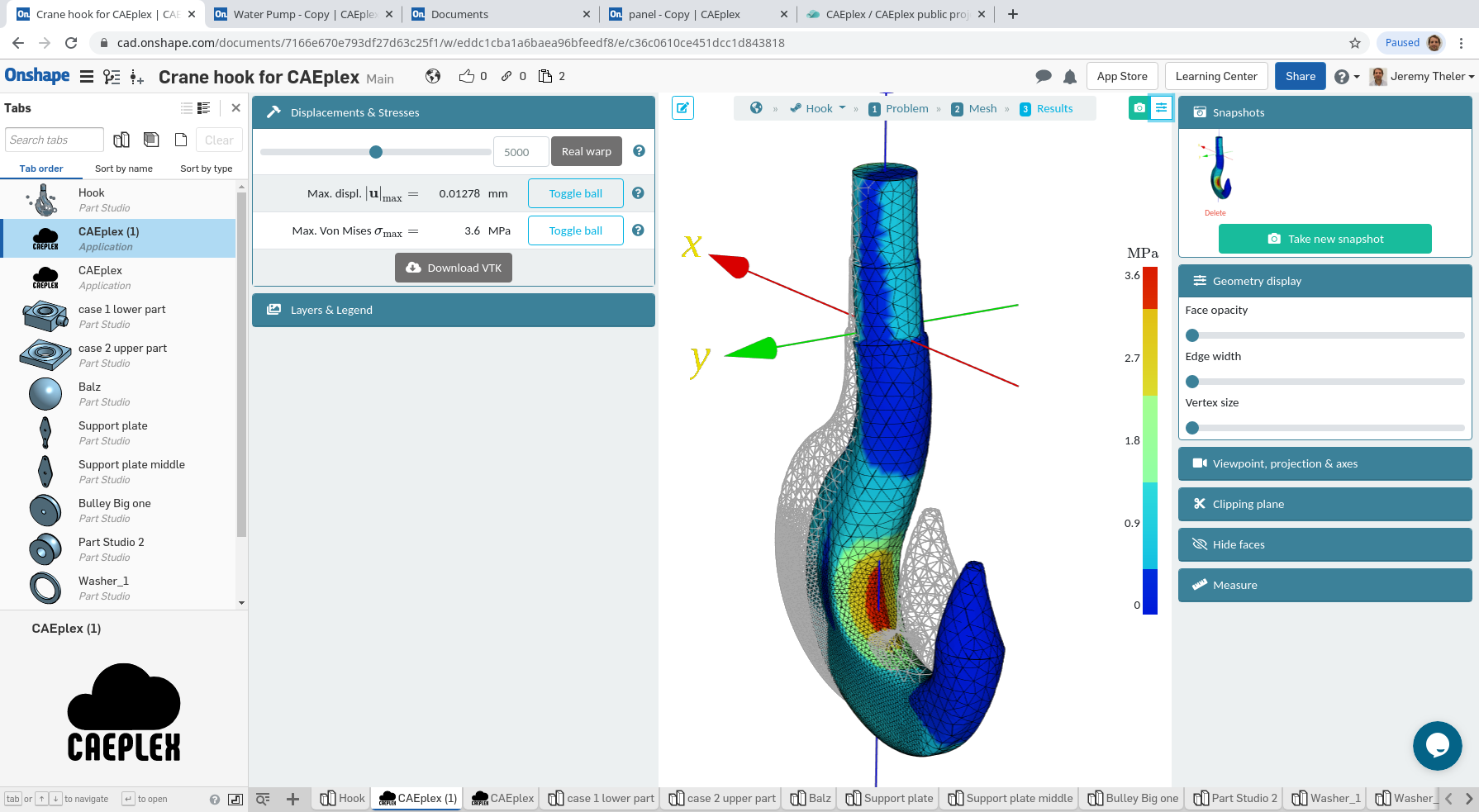

Say you manufacture crane hooks and you design them with a CAD tool, hopefully from your browser directly on the cloud. Do you know how many tons the hook can withstand? If you do CAE after CAD, you can tell.

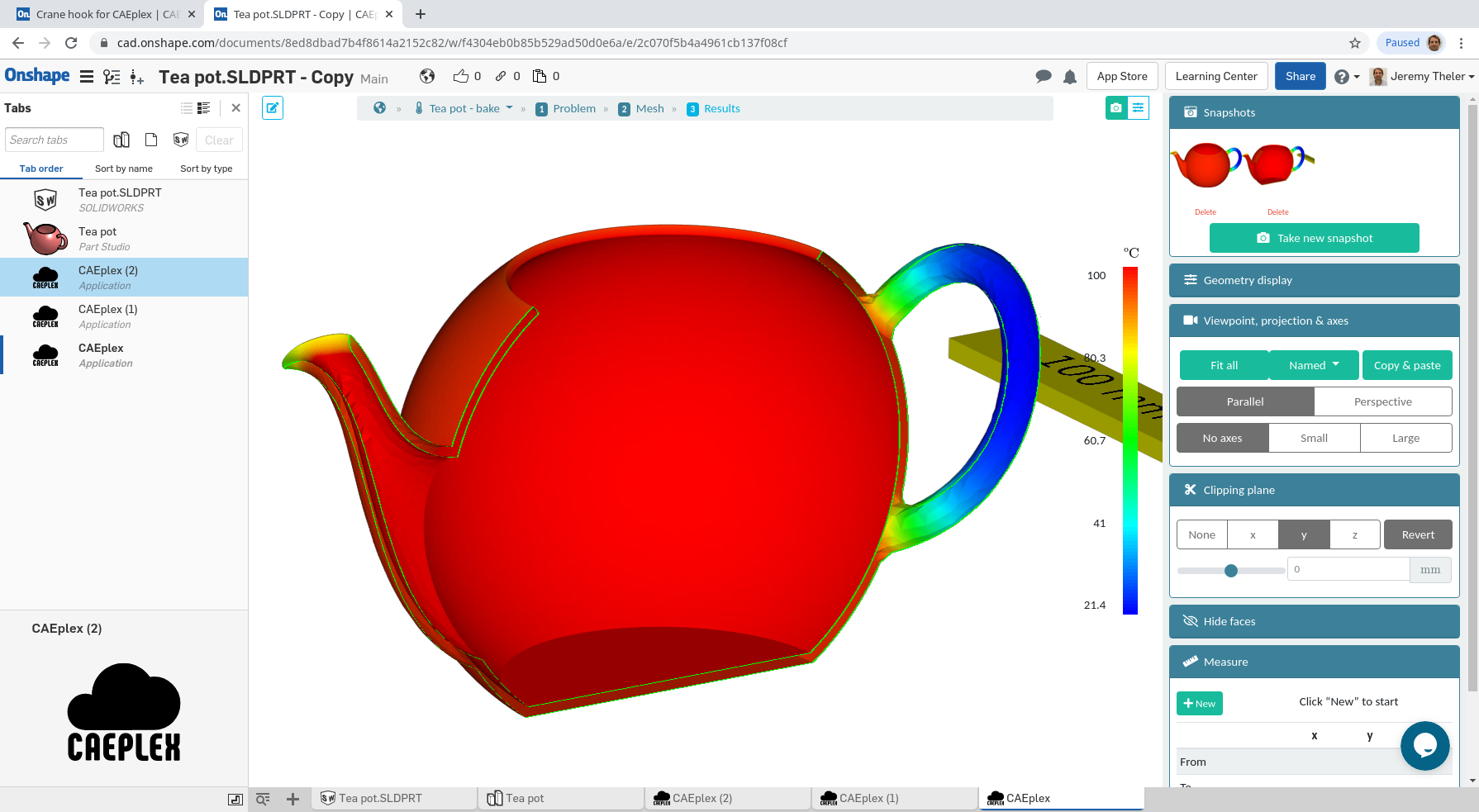

Or maybe you have designed a teapot from scratch (hey, someone has to). Do you know the temperature on the handle when the pot is filled with boiling water?

4. Reduce costs

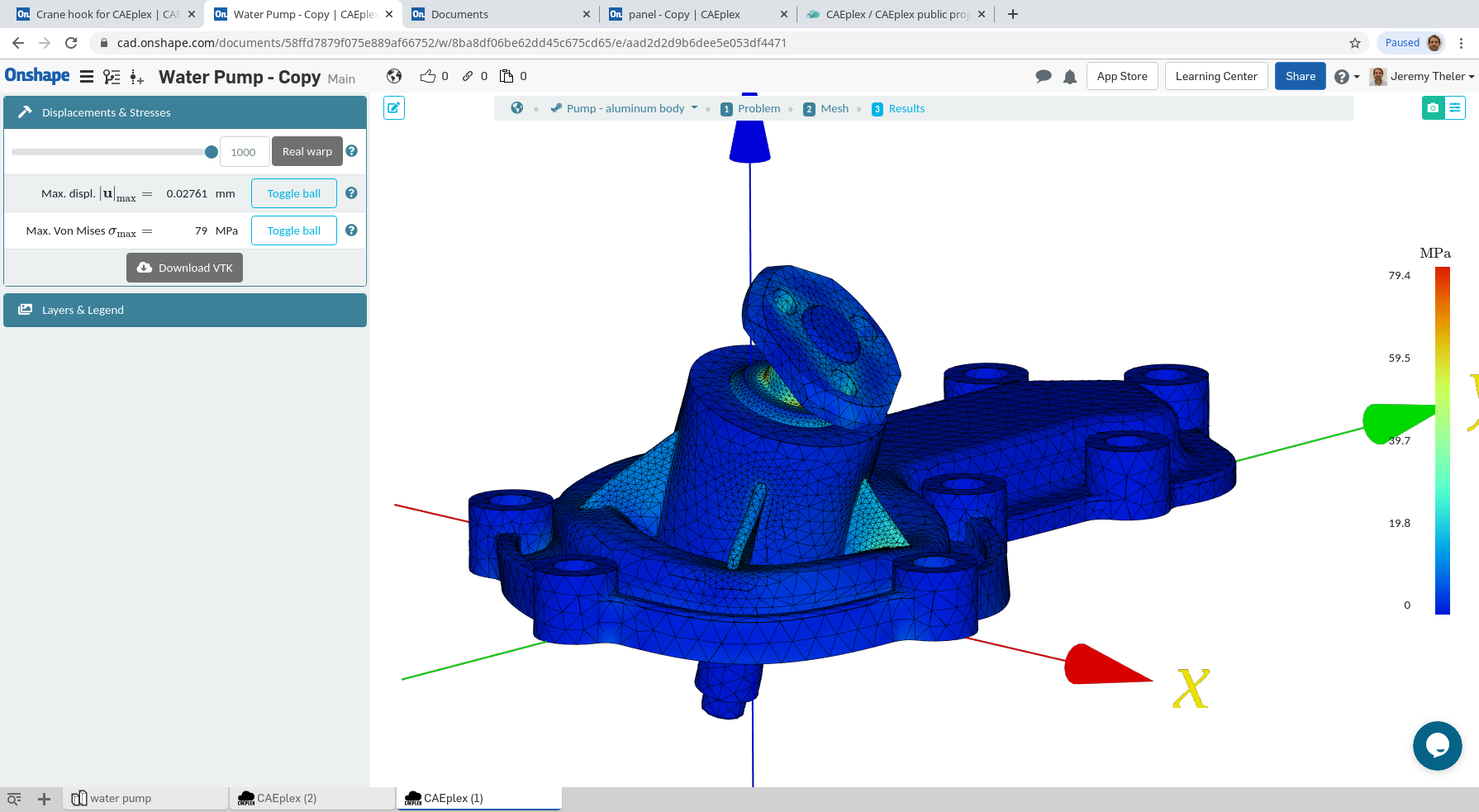

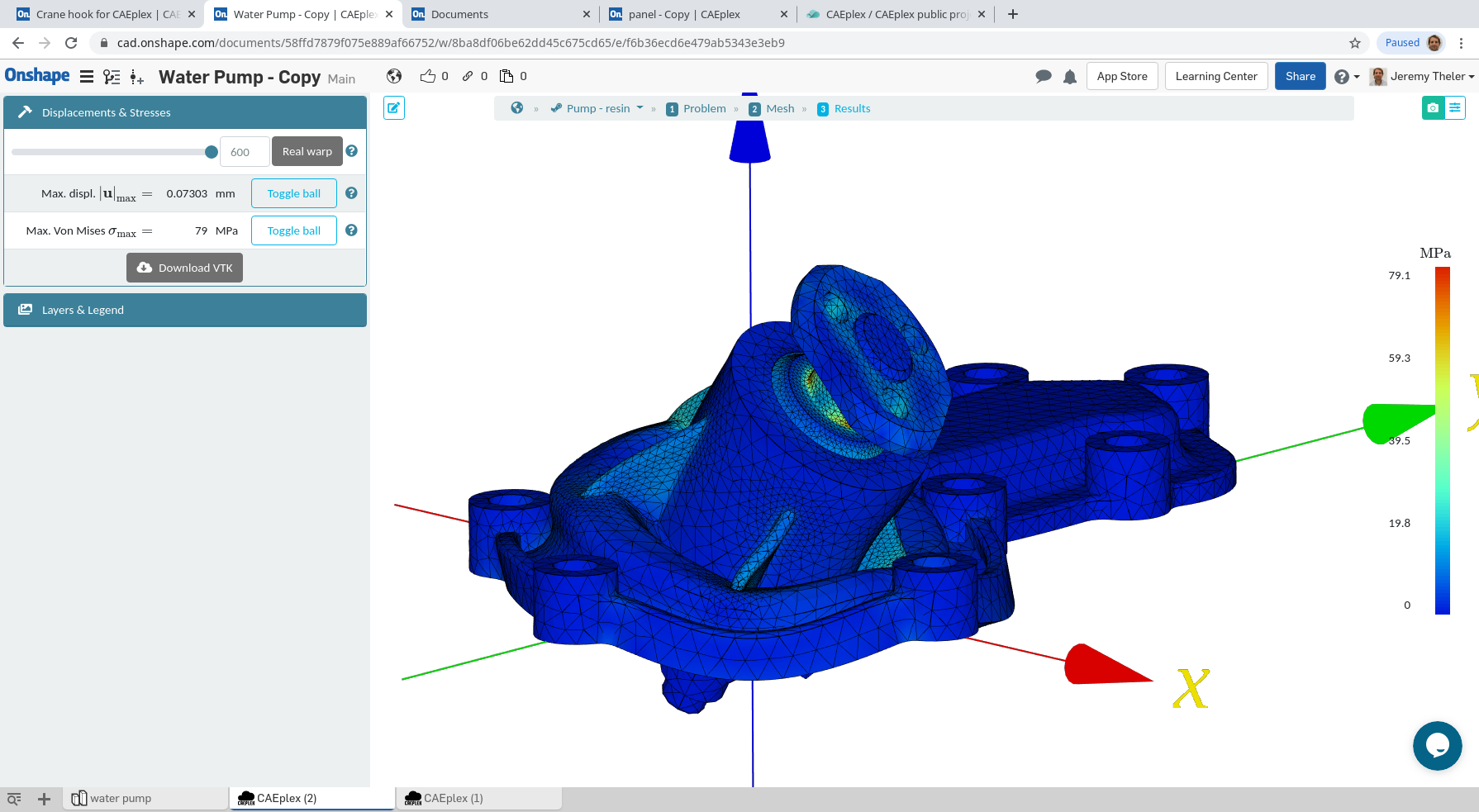

But what about the question of how your parts would behave if the design changed a little bit in order to make the part cheaper? What if the body of a water pump for cooling an internal combustion engine was changed from aluminum to syntherized polymeric resin? Would it resist the mechanical load from the belt through the pulley?

Another couple of examples: can some mass be removed from casted parts without significantly affecting the overall mechanical behavior? What if the design changed so as to need less machining steps?

3. Improve performance

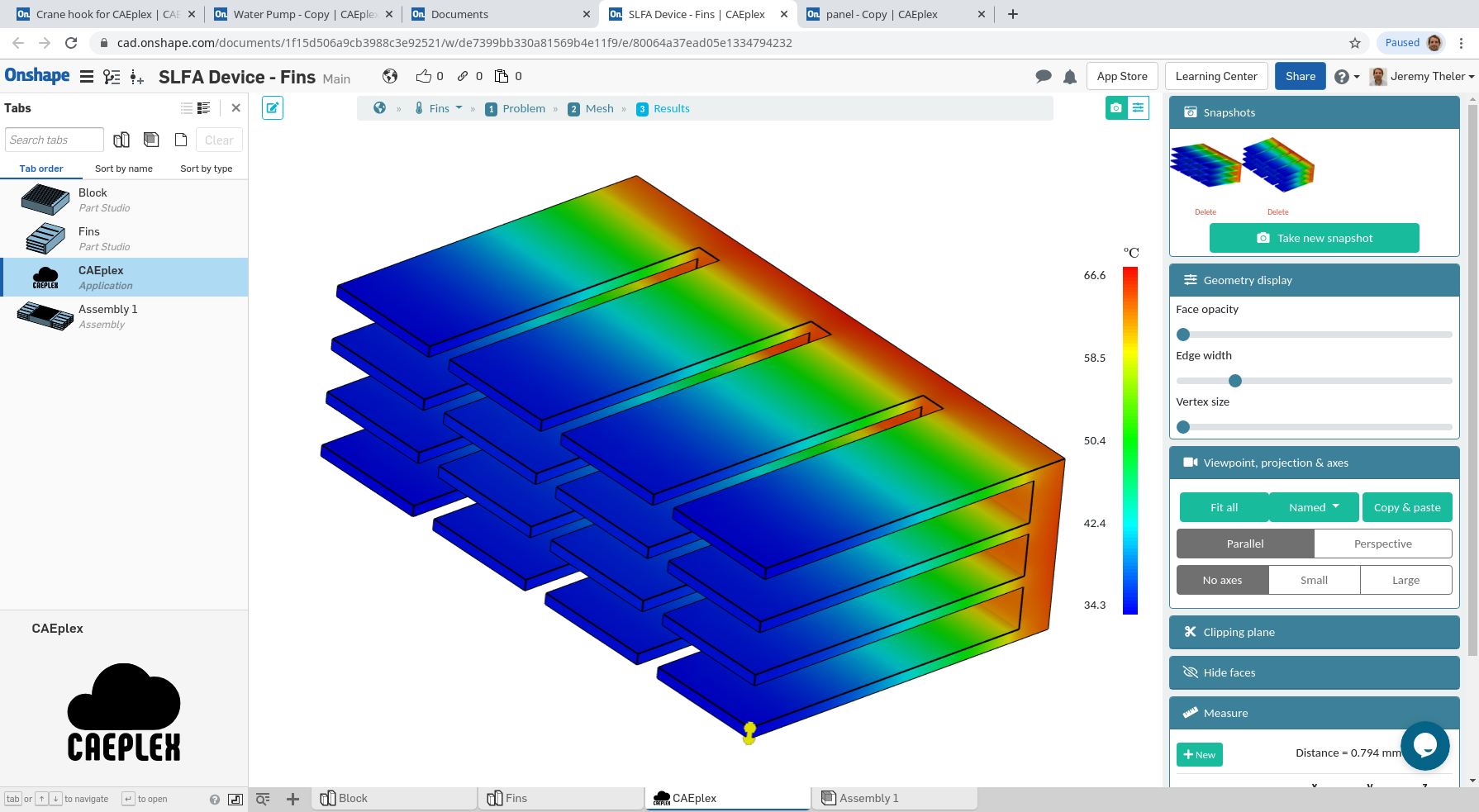

So you do know how your designs behave and how to make them as cheap to manufacture as they can be. Now, can their performance be improved? Are the fins that dissipate heat using natural convection lowering the core temperature (i.e. removing thermal power) as much as they can?

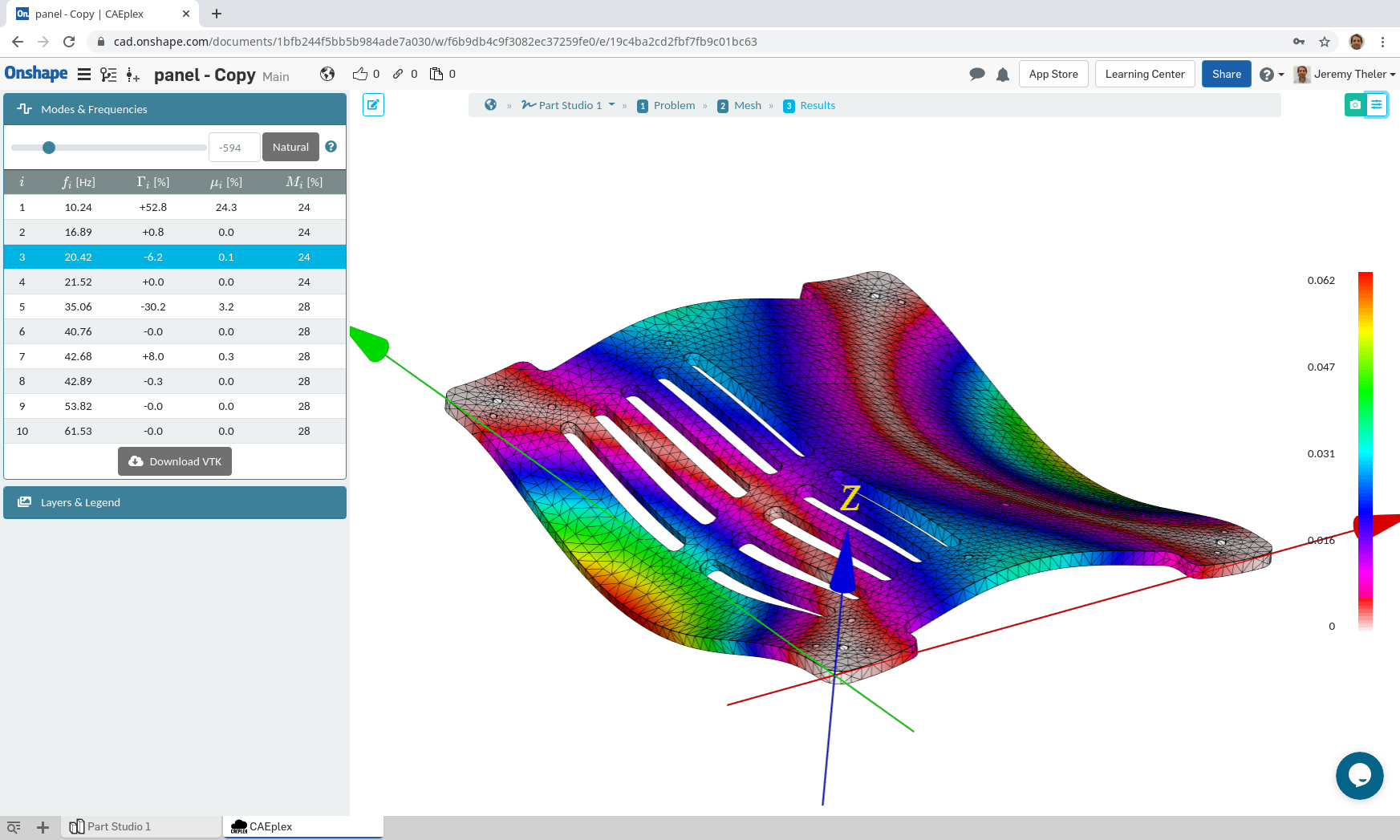

What if small protuberances shift the natural oscillation frequency of a panel such that it does not get excited by rotation of nearby machinery?

2. Learn & practice

If you manage to develop skills on computer-aided engineering, you will for sure face a profitable career in the future. If you are new to the world of engineering analysis, taking a little step from CAD to CAE can leap your capabilities forward. And if you are already a seasoned analyst, adding CAE to your CAD allows you to practice and recall what you already know.

There are plenty of sites, blogs and platforms that will enable you to either get onboard into the world of CAE or get in touch with other specialist to discuss theory and practice. Besides searching online, I recommend the EnterFEA Blog and the Q&A site SimShelf.

1. Because it is quick & easy

This is my favorite reason! CAE is (if presented correctly) quick, easy & fun!

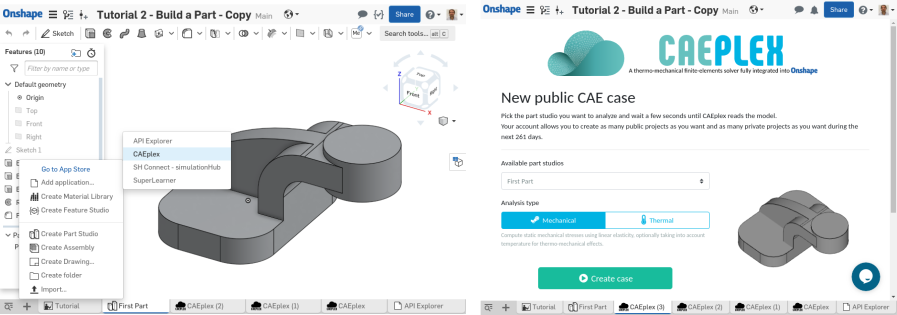

- Subscribe to CAEplex in the Onshape App Store

- Open your part, click on the plus sign, then select “Add application” and choose “CAEplex”

- Pick the part studio to analyze, select the analysis type and click “Create case”

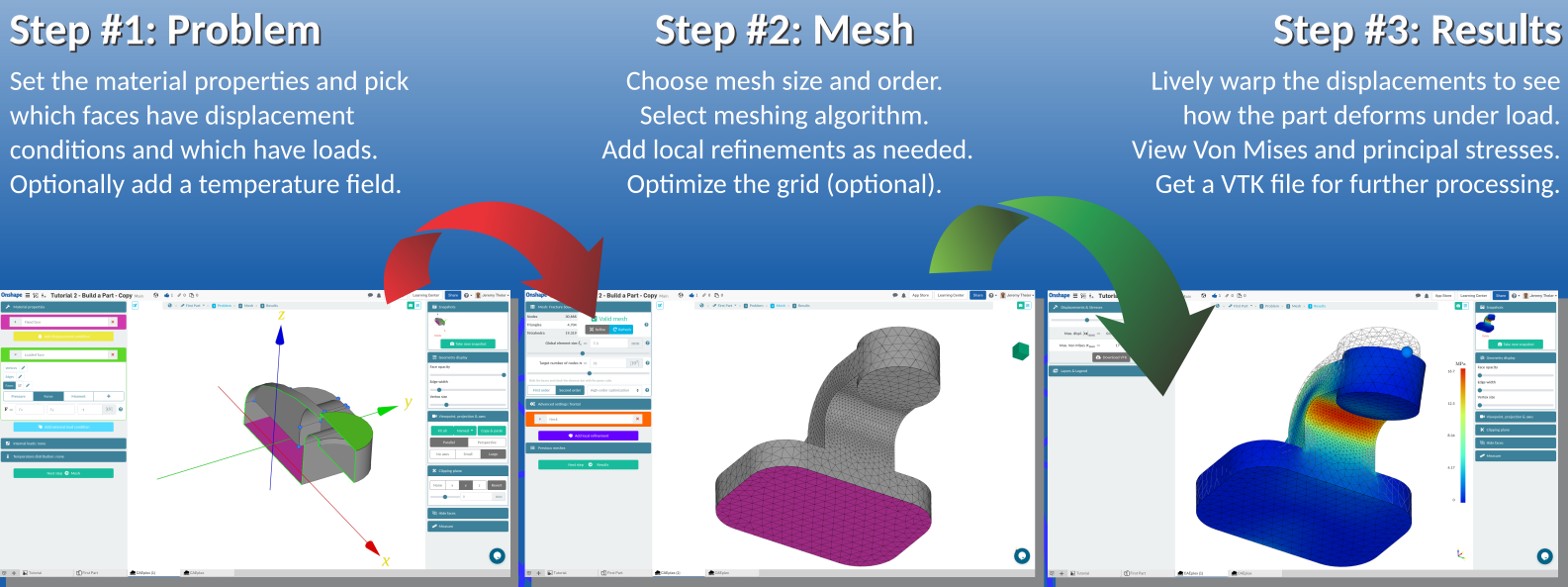

You can then obtain results in less than one minute with our 3-step workflow:

Happy computer-aided engineering in the cloud!1

All of the examples above are based on public projects made online in Onshape and analyzed with the CAEplex App.↩︎